- Home

- Welding Equipment

- Controls and Transformers

- Mid Frequency Inverter, Resistance Welding Control

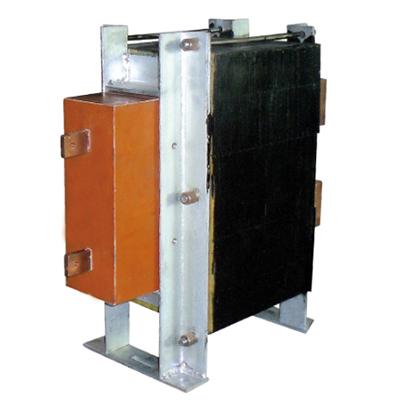

Mid Frequency Inverter, Resistance Welding Control

The mid frequency inverter can increase the frequency of a resistance transformer from 50/60Hz to 1000Hz to decrease the weight of its iron core, reduce secondary inductive losses and control energy and operating costs. It can be paired with automatic electrode-holders to form a portable and lightweight welding equipment set with excellent performance.

- The amount of splashing is largely decreased for a high quality weld and a clean, safe, and comfortable welding environment

- Accurate control of welding parameters in 1 millisecond for the consistent welding results of multilayer steel plate, thick steel plate, high strength steel sheet and aluminum alloy

- Basic building blocks of an inverter and in-process monitoring of weld quality and data monitoring

- Stable welding control system to prevent weld defects

- Three-phase electric power system and medium frequency welding

- No capacitance compensation cabinet

- Small volume and light weight. Compatible with suspension welders

- HMI operator interface for easy operation

| Model | EX-400 | EX-720 | EX-1100 | EX-1980 |

| Input voltage | Single phase/three phase 220/380V+-15% | |||

| Rated frequency | 50/60HZ | |||

| Transformer voltage | DC500V | |||

| Working frequency | 1KHZ-8KHZ | 1KHZ-4KHZ | 1KHZ-2KHZ | 1KHZ-2KHZ |

| Current pattern | 00MF/DC | |||

| Maximum output current20% | 400A | 720A | 1100A | 1980A |

| Continuous output current100% | 120A | 230A | 400A | 630A |

| Control pattern | KSR/KUR/KST | |||

| Current feedback pattern | primary/secondary | |||

| Operating display | text/HMI/PC | |||

| Data range(group) | 7 | 256 | 64K | 64K |

| Controlled equipment | Spot Welder/Projection welder/Seam Welder3T/Seam Welder1T/Suspension welder等 | |||

| Communication station number | 43472 | 1-255 | 1-255 | 1-255 |

| Protocol | 9600,7,E,1 | |||

| Communication form | RS485/RS232 | |||

| Control process | +-1% | |||

Since our establishment in 1999, Darui has been engaged in the design and production of various types of resistance welders, including spot welders, butt welders, seam welders, and more. We have the capabilities to offer you with superior custom service according to your different welding requirements. Our welding machines are widely applied in the manufacturing of home appliances, aviation equipment, electronics, automobiles, furniture, etc. We have earned the trust of customers at home and abroad.

-

- Add.:

No.7 Huaguang Road, Guanbian Village, Hengjiang, Yanbu, Dali Town, Nanhai District, Foshan City, Guangdong Province - Tel.: +86-757-85770767

- Add.: